Container Weighing - Straddle Carrier

No weightbridge

The customer, a container terminal, wanted to weigh all containers during the existing workflow. It was important for the port to avoid having to install one or more weighbridges where the straddle carriers would have to go to weigh the containers. When you think about it, weightbridges can be very impractical in ports. Straddle carriers will have to go and queue up at the weighbridge. There can be congestion and when finally weighing the container, there can be confusion and sometimes mixing up of container and weight. The weighing itself is not very accurate as the weighbridge also will have to weight the entire straddle carrier thus adding significantly to the tare weight. Finally, weightbridges requires detours and extra carbon emissions. Moreover, space was scarce and expensive at the port and straddle-time was also a limiting factor. When thinking about it, it was not so strange that the port was looking for a different approach.

The solution

The solution installed by Tekfa weighs the container directly on the straddle carrier itself. The weighing process lasted 5 seconds on average, the installed system transmitted the weights wirelessly to the customer's server, where the weights of the containers were stored for later use. The port also wanted the driver of each straddle carrier to have a live view on a screen to know if the weight of a container was unevenly distributed between the four corners of the container. This objective was also met.

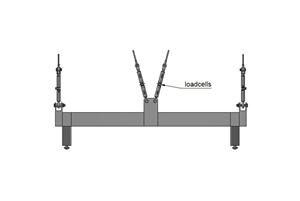

The picture below shows a straddle carrier, a Kalmar ESC 350, while it is weighing a test module that TEKFA built, where the weight was unevenly distributed.

The project was successful and today almost all straddle carriers at the terminal are equipped with TEKFA's weighing system, corner weight display in the driver's cabin, wireless transmission to the server and communication to terminal operating system (N4 Navis).

Solas and VGM compliance

For Tekfa’s customer this project was key to get to know the verified gross mass (VGM) of container ships. This is a duty within the SOLAS convention (the international convention for the Safety Of Life At Sea) that has been getting much more attention during recent years.

As it turns out, it is the shippers’ responsibility to know the VGM of containers whereas it is the port, that most economically can install and operate the accurate and efficient weighing system delivered by TEKFA.