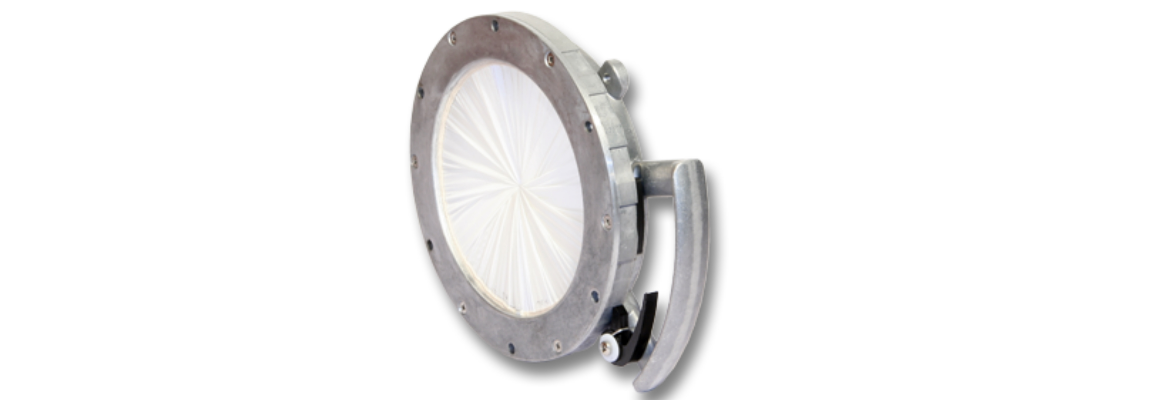

H Iris valve

The Series H Iris valves are designed specifically for open discharge applications on outlets of small and intermediate bulk containers (Rigid IBCs). The H valve is suitable for handling materials with bulk densities up to 900 Kg/m³. This low cost, compact valve has been fitted to many thousands of IBC's the world over. Its popularity with operators is owed to its ease of operation, reliability and excellent regulation of discharge rates.

Technical specifications

- Material: 100mm, 250mm and 300mm diameter Iris valves are produced from gravity die cast aluminium with an anodised finish

- Material: 150mm and 200mm diameter Iris valves are produced from high pressure die cast aluminium with an anodised finish

- Operation: Hand operated

- Bore sizes: 100, 150, 200, 250 and 300mm

- 150mm & 200mm valves have multi notched bodies as standard

- Diaphragm: Single diaphragm for dust tight closure

- Contact parts: FDA approved contact parts

- In-situ diaphragm adjustment

- Option: Additional notches for enhanced flow regulation

- Option: Quick release transit cover with gasket for extra security during transportation of IBCs

- Option: Quick release adaptor for valve mounting (150mm and 200mm Iris valves)

- Option: Stainless steel Top Clamp Plate (Subject to special quotation)

Application

- An outlet valve for the regulation of material flow from the bottom of Intermediate Bulk Containers

- Outlet valve on Dust Collection Hoppers

- Glanding around plastic pipes on extrusion cooling baths

- Choking the 'necks' of Big Bags, where a smaller valve is required

- The H Valve can be certified for ATEX Zone 22D provided that an Anti-Static diaphragm material is used

Drawing

To get a STP file, please contact us.