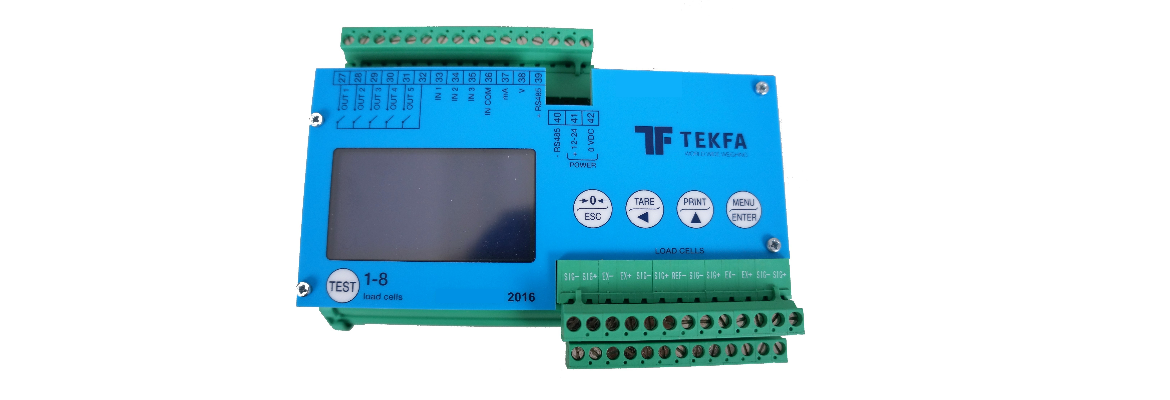

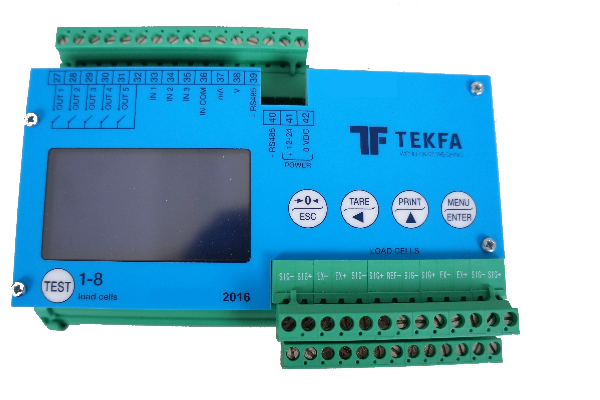

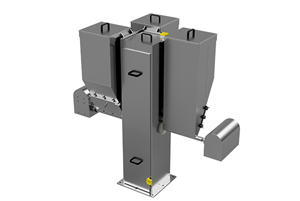

MK-835A weighing transmitter

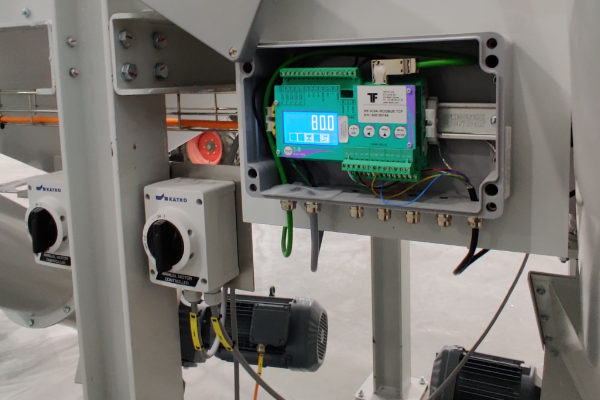

The MK-835A weight transmitter has 8 independent reading channels for load cells to be used for monitoring and direct management of the individual load cells connected. The transmitter has the same benefits and performance of an advanced digital weighing system even using analog load cells. The MK-835A unit is a DIN rail mounted transmitter. The transmitter has LCD display and a five-key keypad for system calibration and a Test key for direct access to diagnostic functions. The MK-835A is designed to store the percentage value of load distribution for each channel.

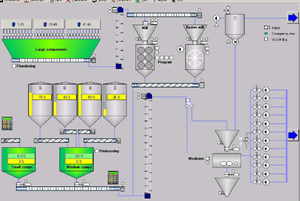

The diagnostic function makes comparisons between the recorded values and if a significant variation between the values is detected during normal operation, the instrument displays an alarm alternating with the weight value. Depending on the weighing system type it is possible to perform: Load automatic diagnostics, load distribution control in constant barycentre systems (e.g. liquids silo), and Automatic diagnostics on zero, check on load cells drift state (e.g. silo, weighbridge, platforms).

Available mounted in a stainless steel box, aluminum box or just the instrument as e.g. a spare part.

Options

- RS485 and 16-bit analog out-put (option)

- CANopen (Option)

- DeviceNet (Option)

- PROFIBUS DP (Option)

- Modbus/TCP (Option)

- Ethernet TCP/IP (Option)

- Profinet IO (Option)

NB: By choosing another option, analog out-put cannot be used.

Technical data:

- 8 weighing channels (supervision and direct control of each connected load cell)

- Analog output 0-20, 4-20mA/0-10V

- 3 logic inputs

- 5 logic relay outputs

- RS485 serial port for connection to PC/PLC, remote display and printer

- Zero-setting of weighing system

- Theoretical calibration by using buttons

- Dead weight calibration

- 3 configurable inputs to be used for net/gross function, semi-automatic zero, peak, print and remote control

- 5 setpoints configurable as normally open or normally closed or remote control.

- Setting of hysteresis value for each setpoint

- Peak & Anti Peak

- Filter to stabilize the weight variations

- External 0-setting of the weighing system

- Semi-automatic tare and predetermined tare (net/gross weight)

- Automatic zero setting at power-on

- Zero tracking and Semi-automatic zero

- Linearization (8 set-points)

- OIML approved

MK-835A: Installation and User manual